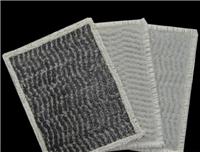

GCL swelling waterproof blanket

GCL swelling waterproof blanket

|

|||||||||||||||||

GCL swelling waterproof blanket is a specialized water features for artificial lakes, landfills, underground garage, roof garden, pool, yard chemicals, oil depots and other anti-leakage of geosynthetics, it is made of high expansion sodium bentonite compound filled in a special non-woven geotextiles, with a needle into the legal system of bentonite impermeable pad can form many small fiber space, is not as bentonite particles flow in one direction, when the water in the pads within a uniform high-density gel waterproof layer, effectively prevent water leakage. GCL waterproof blanket GCL is a cross between an impermeable liner GCL (site of compacted clay liner liner) and polymer materials ---- geomembrane between. Mainly used in environmental engineering waste landfill, underground reservoirs, underground infrastructure construction projects to address the sealing, isolation, anti-leakage problem, the effect is good, strong anti-destructive. II. Principle mineralogical name of bentonite montmorillonite, a natural chemical composition of bentonite into sodium and calcium are two categories. With the water swelling characteristics of bentonite, calcium bentonite general expansion when its expansion is only about three times its own volume, and adsorption of sodium bentonite with water five times its own weight of water, volume expansion to the original 15-17 times above, the sodium bentonite locked between two layers of geosynthetic materials, protecting and strengthening the role of the GCL has a certain overall shear strength. III. Waterproof features 1. compactness: sodium bentonite to form a high density diaphragm under pressure state, a thickness of about 3mm, its permeability to & × 10ˉ11m / sec or less, equivalent to 100 times the density of 30cm thickness of clay , it has a strong self-protection water performance. 2. With a permanent waterproof performance: Because sodium bentonite-based natural inorganic material, even after a very long time or the surrounding environment changes, aging or corrosion will not occur, and therefore lasting waterproof. 3. The construction is simple, short construction period: and other waterproof materials, the construction is relatively simple and does not require heating and paste. Just bentonite powder and nails, washers, etc. are connected and fixed. After construction does not require special inspection, if found defective water is also easy to repair. GCL waterproof material existing in the shortest construction period. The temperature effect is not: in cold weather conditions are not brittle fracture. 5. Integration of waterproof materials and objects: sodium bentonite water when, having 20-28 times expansion capability, even if the concrete structure vibration and settlement, GCL bentonite can repair cracks in the concrete surface within 2mm. 6. Green: Bentonite is a natural inorganic material, harmless, non-toxic, no particular impact on the environment, with good environmental performance. Features: High cost performance, use very extensive. Product range up to 6 meters, greatly improving the efficiency of construction. Scope and application conditions apply to municipal (landfill), water conservancy, environmental protection, artificial lake and building underground water, seepage. In the traditional waterproof material can not be under construction of negative temperature (-20 ℃) ??still construction; in damp grass (but not out of water) is also available construction; construction in the rain and snow can not; not suitable strong acid, strong alkaline solution seepage; Since bentonite-based inorganic material, so the durability of organic waterproof material in four GCL main technical indicators: Bentonite expansion coefficient (ml / 2g) ≥24; GCL mass per unit area (g / m2) ≥4500; GCL longitudinal breaking strength (KN / m) ≥10; GCL transverse rupture strength (KN / m) ≥10; GCL longitudinal elongation at break (%) ≤10; GCL transverse elongation at break (%) ≤6; GCL vertical permeability coefficient (cm / s) ≤5 × 10-9; GCL peel strength (N) ≥65; GCL anti hydrostatic testing (0.5Mp) 24 hours without leakage. ?? GCL is mainly used in what areas? What are the characteristics ??? Can be used for artificial lake waterproof, basement waterproofing, tunnel waterproof, waterproof underground railway project, planting roofing, waterproofing and foundation landfill waterproofing. GCL (GCL) is characterized by an excellent barrier properties: bentonite with water seal, with a high resistance to hydrostatic pressure; 2, the construction is simple: low demand for grass, natural overlap, the negative temperature can also be construction 3, a unique self-healing: use water with a swelling bentonite, which can repair the defect healing impervious layer; 4, durable, environmentally friendly: bentonite belong inorganic material, no aging, good durability; 5, unique breathability: good air-water exchange, so that the water around the plant health swelling waterproof blanket is a specialized water features for artificial lakes, landfills, underground garage, roof garden, pool, yard chemicals, oil depots and the like anti-leakage of geosynthetics, it is made of high expansion sodium bentonite compound filled in a special non-woven geotextiles, with a needle into the legal system of bentonite impermeable pad may be formed of many small fiber space, bentonite particles can not flow in one direction, like when the water to form a uniform high-density gel waterproof layer in the pad, effectively prevent water leakage. GCL is a cross between an impermeable liner GCL (site of compacted clay liner liner) and polymer materials ---- geomembrane between. Mainly used in environmental engineering waste landfill, underground reservoirs, underground infrastructure construction projects to address the sealing, isolation, anti-leakage problem, the effect is good, strong anti-destructive. II. Principle mineralogical name of bentonite montmorillonite, a natural chemical composition of bentonite into sodium and calcium are two categories. With the water swelling characteristics of bentonite, calcium bentonite general expansion when its expansion is only about three times its own volume, and adsorption of sodium bentonite with water five times its own weight of water, volume expansion to the original 15-17 times above, the sodium bentonite locked between two layers of geosynthetic materials, protecting and strengthening the role of the GCL has a certain overall shear strength. III. Waterproof features 1. compactness: sodium bentonite to form a high density diaphragm under pressure state, a thickness of about 3mm, its permeability to & × 10ˉ11m / sec or less, equivalent to 100 times the density of 30cm thickness of clay , it has a strong self-protection water performance. 2. With a permanent waterproof performance: Because sodium bentonite-based natural inorganic material, even after a very long time or the surrounding environment changes, aging or corrosion will not occur, and therefore lasting waterproof. 3. The construction is simple, short construction period: and other waterproof materials, the construction is relatively simple and does not require heating and paste. Just bentonite powder and nails, washers, etc. are connected and fixed. After construction does not require special inspection, if found defective water is also easy to repair. GCL waterproof material existing in the shortest construction period. The temperature effect is not: in cold weather conditions are not brittle fracture. 5. Integration of waterproof materials and objects: sodium bentonite water when, having 20-28 times expansion capability, even if the concrete structure vibration and settlement, GCL bentonite can repair cracks in the concrete surface within 2mm. 6. Green: Bentonite is a natural inorganic material, harmless, non-toxic, no particular impact on the environment, with good environmental performance. Features: High cost performance, use very extensive. Product range up to 6 meters, greatly improving the efficiency of construction. Scope and application conditions apply to municipal (landfill), water conservancy, environmental protection, artificial lake and building underground water, seepage. In the traditional waterproof material can not be under construction of negative temperature (-20 ℃) ??still construction; in damp grass (but not out of water) is also available construction; construction in the rain and snow can not; not suitable strong acid, strong alkaline solution seepage; Since bentonite-based inorganic material, so the durability of organic waterproof material in four GCL main technical indicators: Bentonite expansion coefficient (ml / 2g) ≥24; GCL mass per unit area (g / m2) ≥4500; GCL longitudinal breaking strength (KN / m) ≥10; GCL transverse rupture strength (KN / m) ≥10; GCL longitudinal elongation at break (%) ≤10; GCL transverse elongation at break (%) ≤6; GCL vertical permeability coefficient (cm / s) ≤5 × 10-9; GCL peel strength (N) ≥65; GCL anti hydrostatic testing (0.5Mp) 24 hours without leakage. Waterproof blanket construction method: 1, waterproof blanket material larger self, should adopt shovels transport machine handling, laying. 2, waterproof blanket material connection using an overlapping manner. 3, should be waterproof blanket on a slope greater than 10% of the number of laying minimize overlap along the longitudinal direction of the slope, the slope of the GCL must exceed the toe line above 1500mm. D, we will strictly follow submitted to the supervising engineers design waterproof blanket lay to lay, except with the owner or supervision requirements. 4, any equipment used for laying GCL not travel well in Geosynthetics have been laid on top of. When installing waterproof blanket, outdoor air temperature not lower than 0 ℃ or above 40 ℃. 5, all waterproof blanket exposed edges must be immediately pressed with sandbags or other heavy object to prevent wind or waterproof blanket pulled anchor surrounding ditch. GCL is not in windy weather conditions to start, to prevent windblown. 6, waterproof blanket laying way must ensure GCL direct contact with the ground below, exclude folds. Any wrinkled, folded, or are likely to cause soil arching other geotextile material occurs the same situation, in order to avoid folding, folding and arched, we will through the GCL re-laying or cut according to the requirements of technical description and repair to eliminate these problems. 7, waterproof blanket of equipment must be approved by the supervising engineer to use, it does not allow the use of unprotected razor or "quick knife." I, possible damage to the bentonite blanket construction equipment can not be directly applied to the bentonite blanket. Possible laying method is bulldozing running back, the front of the bulldozers before hanging bentonite blanket spread. If the soil machines on Indian soil leaving the car, laying work should continue before restitution. 8, bentonite blanket minimize drag on the foundation laying carpet bentonite, bentonite blanket so as not to cause damage to the surface of contact with the ground. If necessary, you can add up a layer of geotextile temporarily on the ground, in order to reduce damage to the bentonite blanket laying process due to friction caused. 9, bentonite carpet laying and bonding with the slope inclination should be parallel to the direction, if the slope is greater than 4: 1, from the top of the hill or slope in the 1m, bentonite blanket can not have a lateral overlap. 5, lap a, bentonite lap blanket approach is to overlap the end of lap two bentonite blanket. To prevent loose soil or gravel into the landing zone. Waterproof blanket construction requirements: 1, waterproof blanket should be checked before construction grass, grass-roots should be smooth, without potholes water, no stones roots and other sharp objects. 2, waterproof blanket in handling and construction process to try to avoid vibration and shock, the best time to place. 3, in the GCL installation, inspection after the HDPE geomembrane to be installed as soon as possible, to prevent the rain or torn, dirty. Waterproof blanket product protection: 1, waterproof blanket laying should be promptly laid geomembrane to avoid withstand wind and rain erosion; 2, if not timely laying geomembrane should be used after the color of the cloth or film waterproof blanket laying is completed covered to avoid withstand wind and rain erosion; after c, waterproof blanket laying is completed to avoid damage to the vehicle rolling and other foreign matter; 3, bentonite mat after completion of construction shall have mud, dirt, and other debris can damage the seepage the presence of foreign material layer.

Contact Detail

| Company Name: | Chongqing Lu Jieke Technology Co., Ltd. |

|---|---|

| Employee Number: | |

| Annual export: | |

| Year Established: | |

| Contact Person: | Mr. Manager Hu(Manager) |

| Telephone Number: | 023-67521777 |

| Company Address: | New arch Yuzhong District Ambassador City 12 29-13.14, Chongqing City, Chongqing, China |

| Zip/Postal Code: |

Find More Related Products

- 3M double-sided tape 3M9495..

- 3M double-sided tape 3M9495..

- Machinery Factory

- PUR PUR hot melt adhesive m..

- PUR hot melt machine uses a..

- Good quality high temperatu..

- Tianjin pure water equipmen..

- Production quality Pulley /..

- Timing Belt / Pulley / ribb..

- Boutique belt / Pulley / ri..

- Chang Chung-manholes hardwa..

- Meizhou automatic PUR hot m..

- Metal welding sheet metal b..

- Zhongshan nameplate, namepl..

- Willow City GGD side panels..

- Rotary screw nut where the ..

- Import anti-ozone NBR star-..

- FTTH covered wire cable car..

- Focus on R & D boutique bel..

- Customizable Gifts Pulley /..

- Stainless steel 304 electri..